"Taizhou Jinhaoli Sanitary Ware Co., Ltd."was founded in 2009 and is located in Luqiao District, Taizhou City, Zhejiang Province, on the coast of the East China Sea. It is a famous China Stainless Steel Floor Drain Manufacturers and wholesale Stainless Steel Floor Drain Factory. The company covers an area of 6000 square meters and has more than 100 employees.

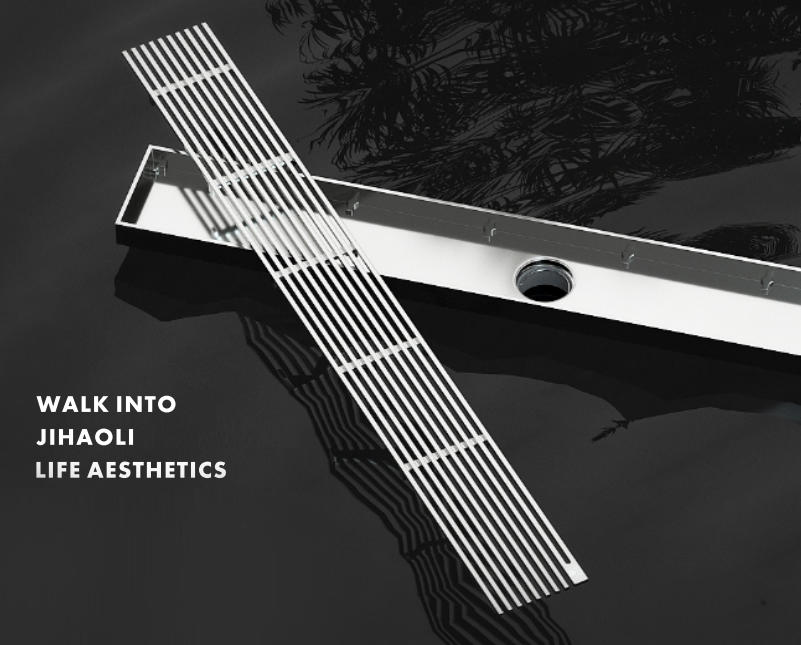

The company has a professional design, manufacturing and management team, and can customize Stainless Steel Floor Drain according to customer needs. It is a professional OEM/ODM Stainless Steel Floor Drain supplier. The company's products mainly include bathroom hardware accessories such as floor drains, basin floor drains, bathtub floor drains, and air-blocking floor drains. The products are mainly medium and high-end, using high-quality materials, carefully polished, advanced electroplating technology and equipment, and strictly implemented in accordance with international quality standards.

Production and testing start from science and technology, from the concept of human nature, closely around the needs of the market and consumers, constantly introduce new ideas, new technologies, new equipment, new talents, and actively develop new products. The company is market-oriented, based on science and technology, and seeks development with integrity. Stainless Steel Floor Drain has a complete range of products, novel styles, prompt delivery and perfect after-sales service. It has won the recognition of new and old customers at home and abroad, and has become a good choice for domestic large-scale building bathroom products.

Professionally committed to the field of household drainage and health.

For customers: to provide customers with more professional bathroom hardware products.

For employees: To provide employees with a platform for happily learning and growing, pursuing career development, and creating a happy life.

To the society: provide a better entrepreneurial platform and take on more social responsibilities!

Use technological innovation to satisfy people's yearning for a better life!.

The development and future success of Jinhaoli are inseparable from the corporate values that we follow together-"Be willing to struggle, take responsibility, share win-win results, sincere cooperation, continuous innovation, and customer achievement".

Grow together with partners and share results.